Once a thriving hub of industry, this Grade II listed flour mill tower has long dominated the landscape, its brick structure standing proudly beside key transport routes that connected it to the wider region.

Built in the 19th century during the height of industrial expansion, the mill played an important role in local economic growth before closing in the late 20th century. Like many historic mills, decades of exposure and neglect began to take its toll.

Over time, the embedded steel within the tower’s brickwork corroded and expanded, creating a jacking effect that threatened both the structure’s stability and its architectural heritage. To protect the tower and prolong its lifespan, a bespoke Impressed Current Cathodic Protection (ICCP) hybrid system was installed, complete with monitoring reference boxes to track the building’s condition well into the future.

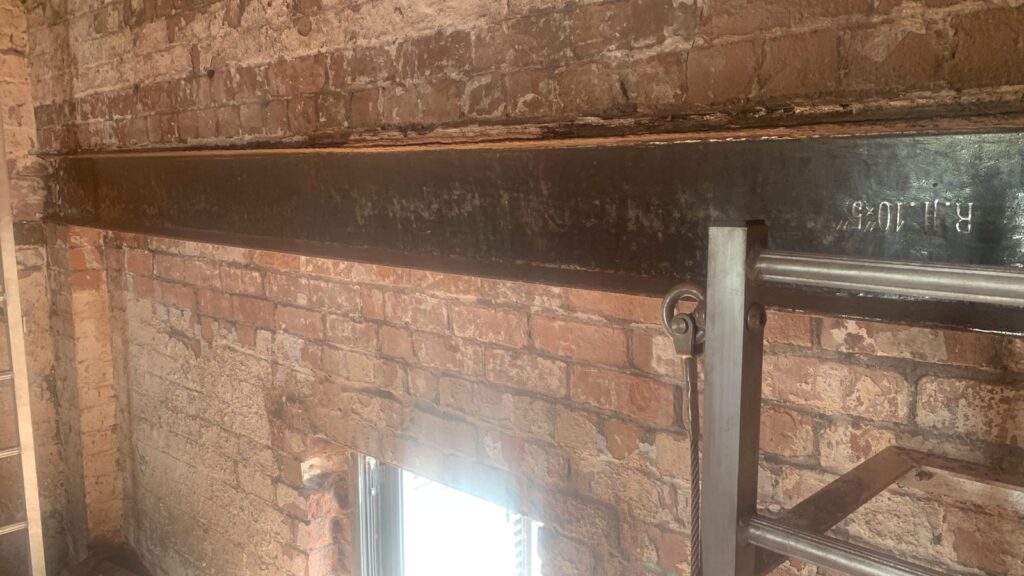

Embedded within the mills brick façade, the historic steel framework was succumbing to corrosion; a slow, powerful force that caused the metal to expand. This swelling exerted pressure against the surrounding brickwork, creating a jacking action that compromised the tower’s structural integrity. Without timely intervention, the stability of this heritage structure would continue to degrade.

Revitalising a listed industrial building demands an approach that balances delicacy with precision. Firstly, the steel corrosion varied across different beams, necessitating a tailored solution. Secondly, the height of the tower and the fragility of the brickwork made access challenging and raised concerns about potential damage during installation. Finally, any work had to honour the building’s Grade II status, meaning minimal visual disturbance and careful preservation of historical features.

A further technical challenge involved ensuring electrical continuity for the cathodic protection system. Voids within the brickwork hindered the flow of protective current around the embedded I-beams. It was essential, therefore, to fill these voids without harming the historic fabric of the tower.

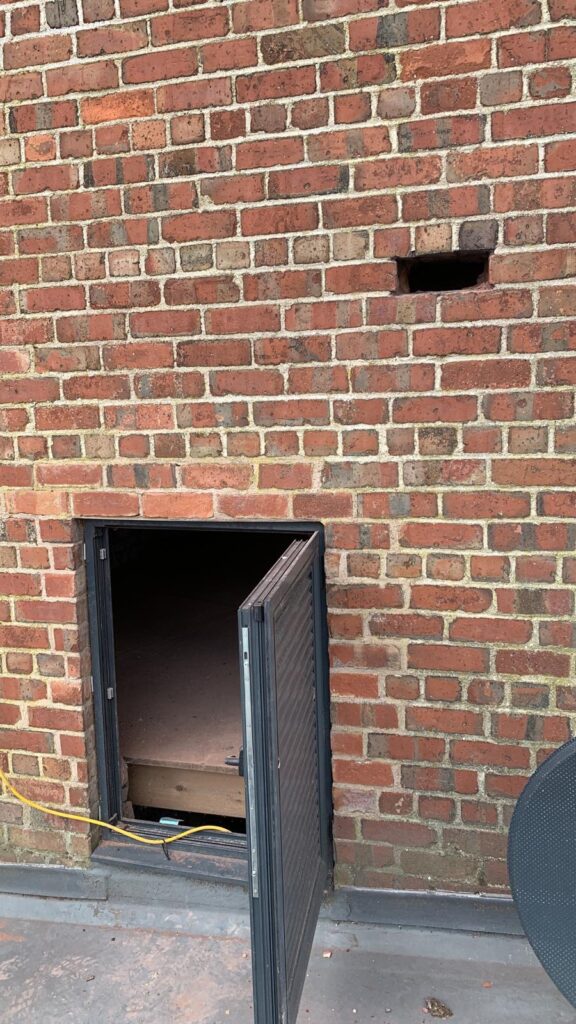

To tackle the corrosion effectively, our team installed a bespoke Impressed Current Cathodic Protection (ICCP) hybrid system, complete with reference boxes for continuous monitoring. The system applies a small impressed current to the steel, mitigating further corrosion and allowing ongoing performance tracking.

Ensuring electrical continuity required filling the voids within the brickwork. Hydrated lime mortar was chosen for its compatibility within historic masonry. Using a Mobile Elevating Work Platform (MEWP), core holes were drilled approximately 20 metres up the structure, and lime mortar was pumped in via a grouting pump, carefully filling the voids and enabling current to flow fully around the I-beams. Half-cell measurements were taken on site to confirm that electrical continuity had been restored effectively.

To manage the differing levels of corrosion, Duoguard anodes of varying sizes were installed, each specified through detailed analysis to deliver the most effective protection for every steel beam.

The installation of the ICCP cathodic protection system has successfully halted further corrosion and eliminated the jacking effect within the brickwork. By stopping the steel from expanding and causing additional structural damage, the system has not only stabilised the tower in the present but also safeguarded it against long-term deterioration. The inclusion of a continuous monitoring system means that performance can be tracked and maintained, ensuring that any potential issues are identified before they develop into significant risks.

This proactive approach has effectively expanded the lifespan of the Grade II listed building, protecting both its structural integrity and its culture for future generations to come.

Contact our team today to find out how CSC Services can help you safeguard your heritage structures for the future.